The IP65 rating defines the protection level an enclosure provides against dust and water ingress, essential for maintaining equipment integrity in testing chambers. The first digit, '6,' signifies total protection against dust, ensuring no particles enter. The second digit, '5,' indicates protection against low-pressure water jets. This rating is critical in food factory environments where hygiene and equipment reliability are paramount. By preventing contamination and damage, IP65-rated equipment helps maintain compliance with food safety standards and ensures efficient operations.

In food processing environments, the IP65 rating is particularly necessary to maintain hygiene and operational efficiency. These areas often face exposure to steam, moisture, and food particles, all of which can compromise unprotected equipment. Using IP65-rated products ensures that equipment continues to function optimally despite such challenges. This level of protection guarantees that operations remain uninterrupted, preventing costly downtimes and product losses.

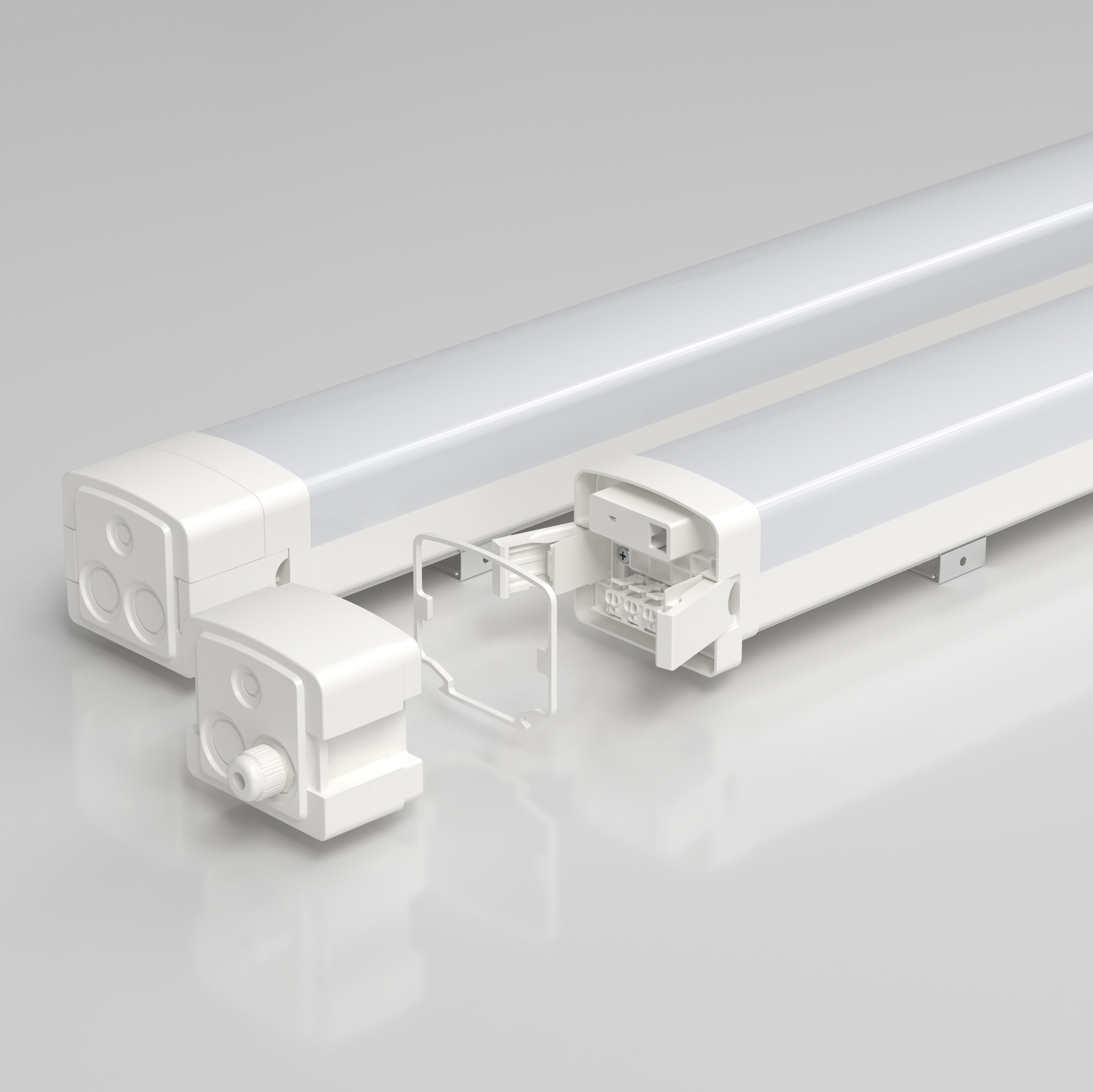

Several industries have successfully implemented IP65-rated products to enhance operational reliability. For instance, the LED tri-proof light, commonly used in industrial settings such as factories and mines, benefits from the IP65 rating to provide durable and safe lighting solutions. According to industry reports, these lights significantly reduce maintenance costs and energy consumption, highlighting their effectiveness in challenging environments. This data underscores the tangible benefits of incorporating IP65-rated equipment to boost efficiency and safety across various sectors.

The IP65 triproof lights are especially designed to provide exceptional waterproof and dustproof capabilities, meeting stringent regulatory standards for food safety. By utilizing materials resistant to oxidation and corrosion, these lights ensure that they remain functional even in humid or dusty environments common in food factories. Their robust construction guarantees compliance with international safety guidelines, making them indispensable for maintaining a hygienic and efficient operation.

Energy efficiency is another hallmark of IP65 triproof lights. Compared to traditional lighting solutions, these fixtures boast energy savings of up to 85% while offering impressive longevity. For instance, some LED triproof lights can operate efficiently for over 54,000 hours thanks to advanced aging tests. This not only reduces energy bills but also diminishes the frequency of replacements, resulting in substantial long-term cost savings and a smaller carbon footprint.

Moreover, the integrated emergency backup options in IP65 triproof lights ensure continuous operation during unexpected power outages. This feature is crucial in food processing environments where any disruption can lead to safety hazards or spoilage. By maintaining illumination in critical areas, these lights enhance operational safety and reliability in compliance with food safety standards. Emergency lighting that automatically engages during power failures highlights the importance of safety measures in maintaining seamless food processing activities.

The use of SMD LED chips in triproof lights has revolutionized their performance across various metrics. They offer improved brightness and reduced heat generation, which lead to enhanced energy efficiency. This technological advancement not only ensures that the lights are brighter and more effective but also significantly contributes to their longevity. As a result, businesses can save on energy costs in food processing environments since these chips can last much longer than traditional light sources while using less energy.

Moreover, high-performance LED drivers play a crucial role in triproof lights by supporting dimming options and increasing adaptability. These drivers are designed to maintain a stable performance across different operational conditions, providing flexibility and better control over lighting levels. This adaptability is vital in food processing environments, where the lighting needs can vary significantly from one area to another. With the ability to fine-tune the brightness, these lights can enhance safety and efficiency, providing the ideal illumination tailored to specific tasks and operational workflows.

When selecting triproof lights for environments like food factories, it's essential to consider durable housing materials that can resist corrosion and impact. IP65 triproof lights, for example, often utilize anti-oxidation and anti-corrosion materials in their construction. These materials, combined with silicone sealing rings, ensure a robust seal that protects the lighting fixture from harsh environmental factors without compromising performance. Such resilience is not only important for maintaining consistent lighting quality but also for minimizing maintenance costs over time.

Equally crucial are the design features that facilitate easy installation and maintenance, making these lights highly efficient in busy environments. Many modern triproof lights come with modular designs and are constructed from lightweight materials. This not only simplifies the installation process but also ensures that maintenance can be carried out quickly, thereby reducing downtime. Moreover, features like various mounting options, including suspended or surface-mounted installations, enable these lights to adapt to diverse operational settings, enhancing overall operational efficiency.

The Food Factory Testing Chamber IP65 Triproof Light is a top-tier lighting solution designed to meet the stringent demands of testing chambers in food processing environments. This fixture stands out due to its waterproof, dustproof, and impact-resistant properties, which make it exceptionally reliable and safe in challenging conditions where food safety and hygiene are paramount.

The technical specifications of this triproof light are impressive: it comes in different sizes—600mm, 1200mm, and 1500mm—with power ratings of 20W, 40W, and 60W respectively. This range provides flexibility in installation based on specific lighting needs. It also boasts an IP65 rating, ensuring excellent protection against dust and water jets, which is crucial for maintaining operation in moist food factory environments. Compared to other available lights, its energy-efficient design offers significant savings on electricity bills over time, contributing to its long-term cost-effectiveness.

One of the primary reasons to choose this specific triproof light is its compliance with international safety standards, ensuring both quality and reliability. Its robust design has been backed by numerous professionals in the industry, highlighting its dependable performance and durability. As a result, it is a favored choice for food factories seeking to enhance operational efficiency and safety through innovative lighting solutions.