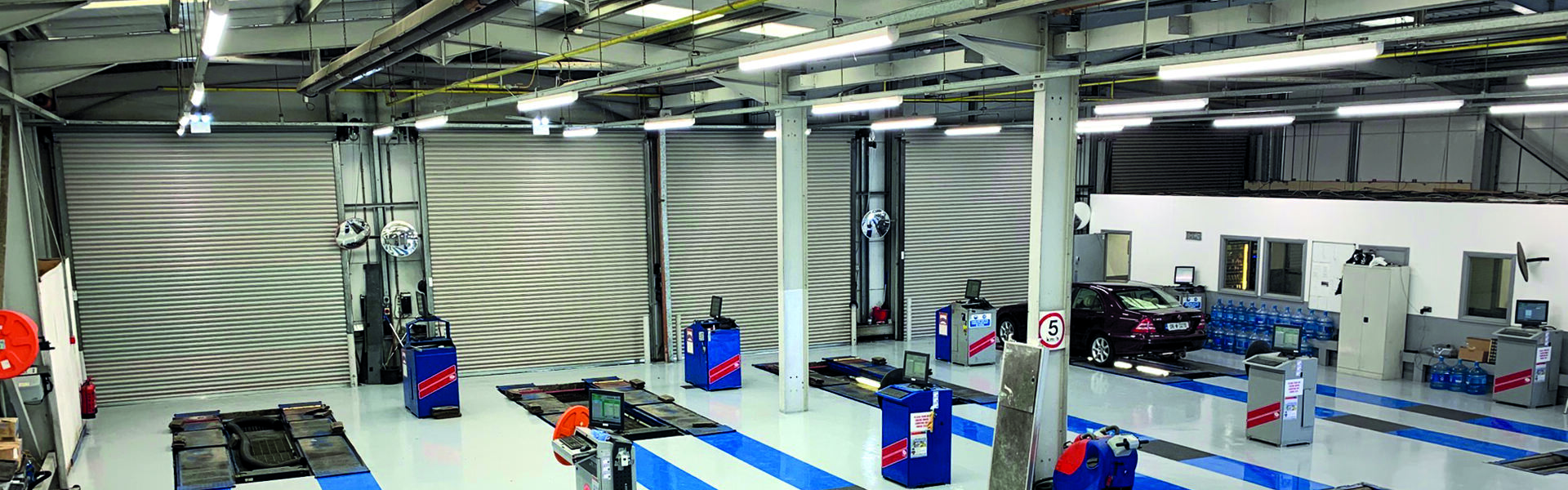

In the heart of a bustling industrial park, nestled among the towering machinery and humming production lines, lies a facility that has embraced innovation in every corner. This factory, known for its cutting-edge technology and commitment to sustainability, recently underwent a lighting upgrade, replacing its traditional fixtures with the TP018 Triproof Light – a versatile and efficient solution that has transformed the work environment in more ways than one.

The Challenge:

The factory faced several challenges with its existing lighting system. The dusty environment, coupled with occasional splashes of water from nearby cleaning operations, had caused premature failure of several light fixtures, resulting in inconsistent illumination and increased maintenance costs. Moreover, the outdated lighting was energy-intensive, contributing significantly to the facility's overall operational expenses. The management was determined to find a solution that could withstand the harsh conditions, reduce energy consumption, and enhance the working conditions for employees.

The Solution: TP018 Triproof Light

After thorough research and evaluation, the factory chose the TP018 Triproof Light as the ideal replacement. Its IP65 rating made it the perfect fit for the factory's demanding environment, ensuring that dust and moisture would no longer be a hindrance to the lighting system's performance. The installation process was swift and seamless, with minimal disruption to the daily operations.

Application Highlights:

Durability and Reliability: The TP018's superior material construction and precise craftsmanship have proven their worth in the factory's challenging environment. Months after installation, not a single fixture has shown signs of wear or malfunction, significantly reducing maintenance downtime and costs.

Energy Efficiency: The energy-efficient design of the TP018 has led to a notable reduction in the factory's power consumption. By using less energy to produce a bright and uniform light, the lights have helped the facility cut down on its electricity bills, aligning with the company's sustainability goals.

Improved Lighting Quality: The soft and even light emitted by the TP018s has created a more comfortable and productive atmosphere for the workers. Visibility has improved across the factory floor, enhancing safety and reducing the risk of accidents. The modern and sleek design of the fixtures also adds an aesthetic appeal to the industrial setting.

Versatility: The TP018's adaptability has been a game-changer for the factory. From the dusty assembly lines to the damp storage areas, the lights have proven their worth in various applications, ensuring that every corner of the facility is well-lit and functional.

Employee Satisfaction: The improved lighting conditions have not only boosted productivity but also enhanced the overall well-being of the workforce. Employees report feeling more energized and focused during their shifts, contributing to a positive work culture.

Conclusion:

The integration of the TP018 Triproof Light into the factory's lighting infrastructure has been a resounding success. It has not only addressed the challenges posed by the harsh industrial environment but has also contributed to cost savings, improved safety, and employee satisfaction. As the factory continues to evolve and expand, the TP018 stands as a testament to the power of innovative lighting solutions in modern industrial settings.

Hot News

Hot News